What Multimatic Means to the Automotive World

The parts supplier is behind some of the automotive industry's most exciting technologies and vehicles.

Chevrolet

Chevrolet

Article QuickTakes:

Branding is an important part of any automaker's corporate tool kit. The auto industry's suppliers that ensure modern vehicles get built using the best possible components and expertise are often less likely to see the spotlight.

Of these stealth firms, Multimatic can count itself as one of the most important partners in automotive parts production, engineering, and the assembly of high-performance supercars.

The Canadian company, which operates primarily behind the scenes, churns out millions of common automotive components every year. It's also busy pushing the limits of what's possible in suspension design on the racetrack and at the upper reaches of the supercar stratosphere.

Ford

Ford

Multimatic Was Founded in the 1950s

There are two Multimatics in the automotive world. The first began in the 1950s when Tony Czapka and Frank Stronach created the Multimatic manufacturing organization. This original Multimatic eventually evolved into Magna International, one of the world's most prominent automotive-parts producers. The current iteration of Multimatic, based in Markham, Ontario, Canada, was founded in 1984 by Peter Czapka, Tony's son, in partnership with Stronach as Multimatic Mechanisms. The younger Czapka later bought out Stronach and is now the sole owner.

Initially, this company was dedicated to supplying the automotive industry with components such as hinges, closures, and aerodynamic systems. Expansion happened quickly. Two years later, Multimatic began to produce suspension parts and structural pieces. By 1989, the company branched further into engineering services for internal projects and external customers, such as Honda Civic bumper beams and Volkswagen Jetta twist-axle stampings.

The company has also made significant strides in the world of automotive racing, starting with the launch of Multimatic Motorsports in 1992. This competition arm was the brainchild of English-born Larry Holt, who moved to Canada in his youth, where his father managed a Toronto Ferrari dealership. The motorsports arm has been highly active in nearly every major racing series.

The success of Multimatic Motorsports has also led directly to the development of the company's Niche Vehicles division. Separated from the Multimatic Engineering group in 2019, Niche Vehicles specializes in producing low-volume road vehicles.

A year later, the company's Special Vehicle Operations was created to perform complete vehicle engineering and support the assembly of Niche Vehicles cars and Multimatic Motorsports ventures.

Each of these internal groups is operated separately under the Multimatic banner.

Ford

Ford

Multimatic Is Active in the Entire Development Process

From design to engineering to manufacturing to final assembly, Multimatic's areas of expertise span the entire vehicle development process.

The first is the company's bread and butter: making automotive parts that are completely anonymous. Examples include the front suspension of the Ford F-150 and the control arms for the Chevrolet Silverado and GMC Sierra light-duty trucks. These components are churned out by the millions, with Multimatic often an active participant in their design.

By merging its automotive parts production and design under the same roof, the business has become an essential partner to many automakers.

Along with running race-car teams, Multimatic is also a prominent motorsport vendor. Brake ducts for the Mercedes-Benz F1 cars, bodywork for the Toyota LMP1 and World Rally Championship programs, and ready-to-race Ford GT4 Mustangs are just a few examples.

Another side of Multimatic is the high-profile projects that enthusiasts are more likely to be familiar with. Arguably, the most famous is the Ford GT mid-engine supercar that debuted in 2015.

Chevrolet

Chevrolet

Innovations Multimatic Brought to the Automotive Industry

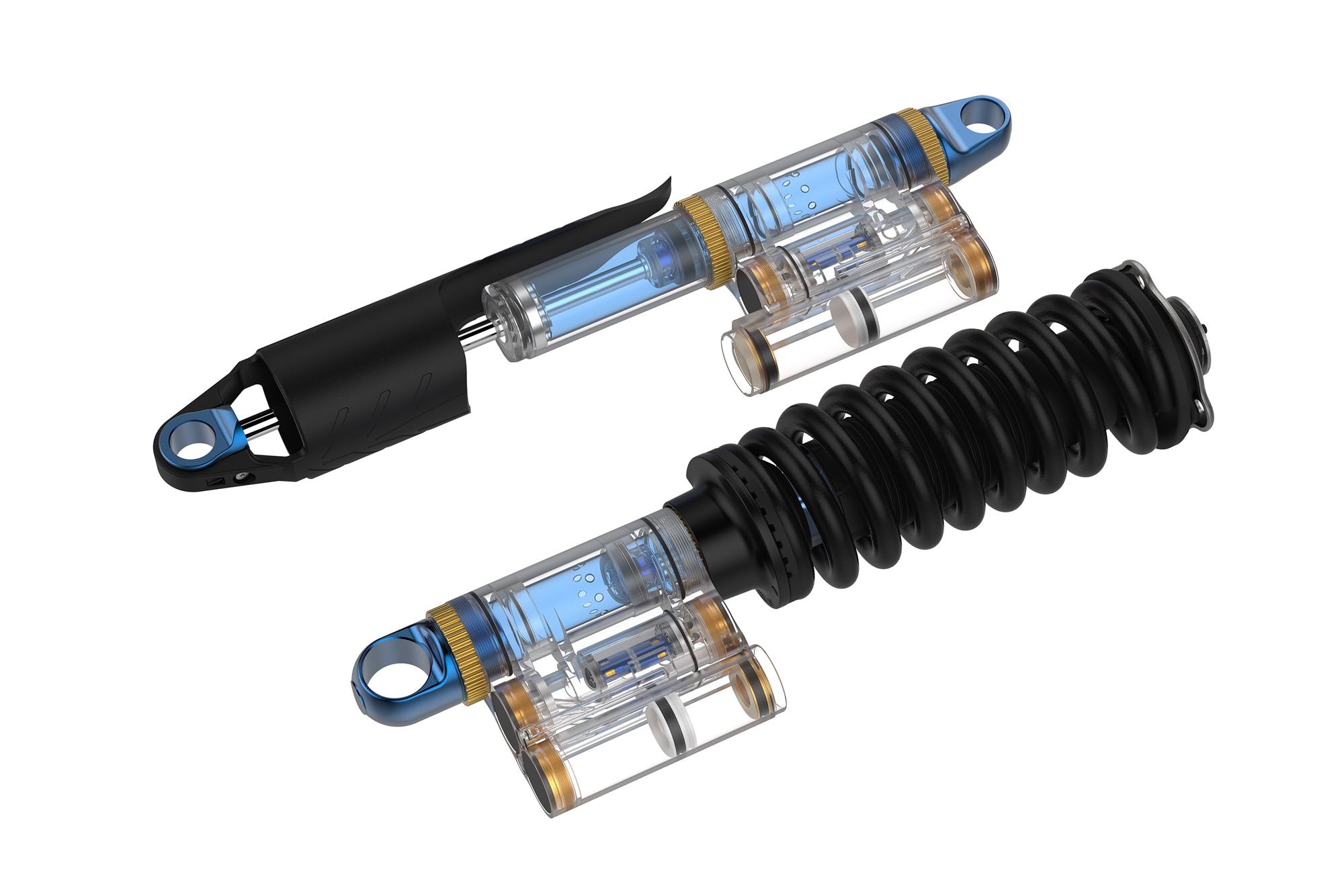

One reason Multimatic has successfully partnered with so many automakers is the company's willingness to innovate. These innovations range from Ford's tailgate step for the F-Series pickup trucks to the patent-pending Gurney flap rear wing on the Ford GT. However, Multimatic's best-known innovation is its Dynamic Suspensions Spool Valve (DSSV) shock absorbers, a significant breakthrough in vehicle suspension design.

These revolutionary DSSV components were developed in-house at Multimatic by way of its engineering department, stemming directly from similar technology that the company initially conceived for use in Formula 1, Formula E, Champ Car, and Grand Touring race cars, debuting back in 2002. By using spool valves in place of traditional external reservoirs or magnetically controlled fluids, these shocks can offer extreme levels of customization and performance without compromising vehicle ride comfort. DSSV shock absorbers have also been applied to exotic production cars from Aston Martin and Ferrari, the Chevrolet Camaro ZL1 1LE, as well as the ZR2 editions of the Chevrolet Colorado and Chevrolet Silverado pickups and their GMC equivalents.

Ford

Ford

Multimatic and Its Role in Supercar Creation

Multimatic has also raised its profile significantly by designing and building high-end supercars for various automakers. The most famous Multimatic effort is the latest Ford GT. Featuring a carbon-fiber monocoque platform, aluminum subframes, and an aero-friendly body design, the Ford GT drew heavily from Multimatic's experience in the motorsports world.

Multimatic is also responsible for the assembly of every third-generation Ford GT. The production GT spawned several race-ready variants, including race cars that won the 24 Hours at Le Mans for Ford and cars available to private customers interested in mounting their own campaigns.

Before the Ford GT, Multimatic engineered and built the 2009 to 2012 Aston Martin One-77. Named after the 77 production examples, the One-77 is the fastest vehicle to wear the famous British brand's badge.

Other road cars of note from the Multimatic portfolio include the Mercedes-AMG One, which offered more than 1,000 horsepower and borrowed extensively from Mercedes-Benz and Multimatic's F1 experience, and 99 copies of the Aston Martin Zagato Shooting Brake.

The Canadian supplier is also responsible for producing the upcoming Ford Mustang GTD. The hyper-Mustang's supercharged V8 engine is married to a transaxle and is a road-legal version of the Blue Oval's Mustang GT3 racer. The most expensive Mustang ever built, the GTD is expected to cost $300,000 when it goes on sale as early as the end of 2024.

Off-road fans are included, too, with the Ford Bronco DR. Using the most rugged application of Multimatic's DSSV shock absorbers to date and a roll cage and highly modified chassis-frame structure, the production desert-racing Bronco is available for those who prefer their motorsports dusty and far from any asphalt.